Hello,

I am simulating a process including strapping operation (like the video). Basically it is to cover a strapping band/wire around an object. The difficulty I now encounter is that I do not know if there is anything I can do to show a strapping band cover the product, maybe it cannot be simulated to be cut from the machine but that is okay as the main thing is to visualize there is a strapping around the product after going through the machine.

Hi @thanhh019,

You could use the “ChangeType” process statement to change the product to another one with strapping around it after the machine process.

1 Like

Hello,

I think it is a great idea. I have tried that. However, the process executor got stuck at that line of command. I have tried to declare the ProductIn variable but it did not work either. I do not how can I modify that variable.

Hi @thanhh019,

It would be better if there is screenshot or short video of the problem you are facing for us to understand better.

Hi,

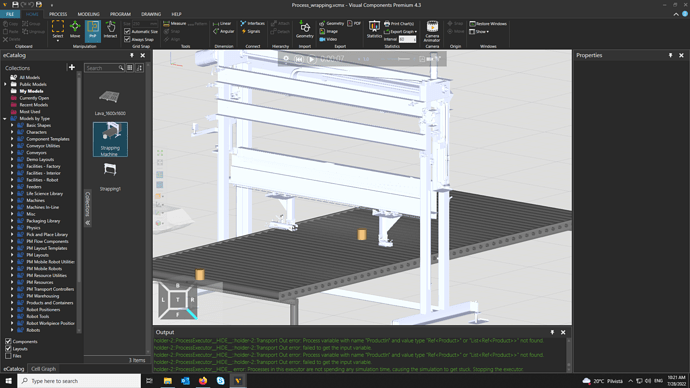

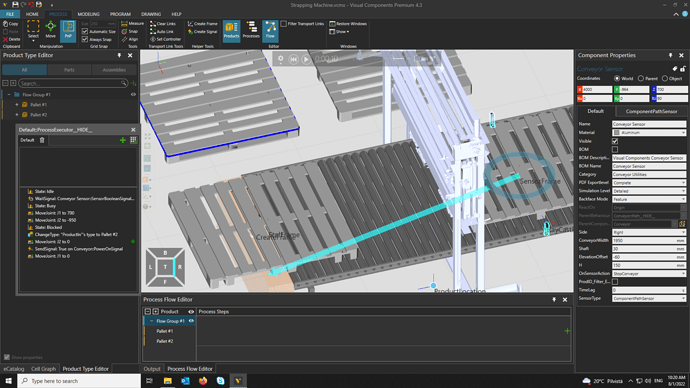

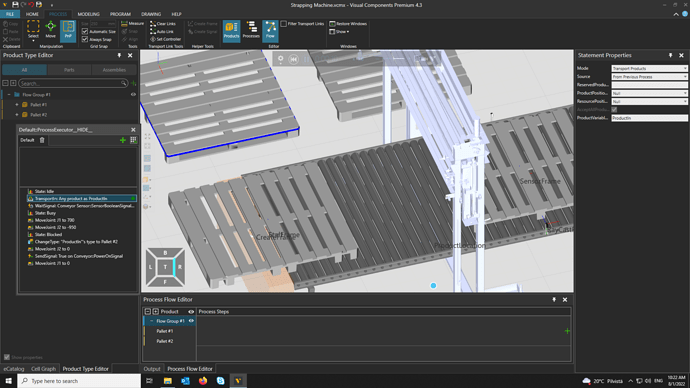

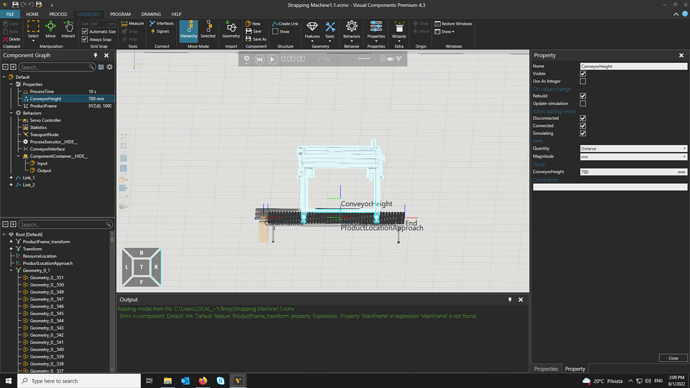

Sorry for that. Here is the basic sketch of the product. Pallet #1 is the normal pallet while pallet #2 is the one with blue stripe. In picture 1, the Process Executor automatically passed my ChangeType command. In picture 2, when I added the ProdcutIn line with hope to declare the ProductIn variable, the process stuck at that line of command and did not execute anymore.

Hi @thanhh019,

In this case, I think you could remove the sensor and use the TransportIn process statement to hold the product on the conveyor. After the machine process, use TransportOut for the product to continue moving.

With this, the ChangeType process statement can be used properly.

Hi,

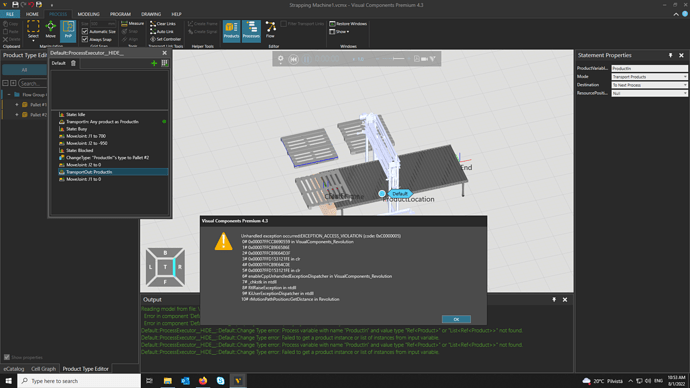

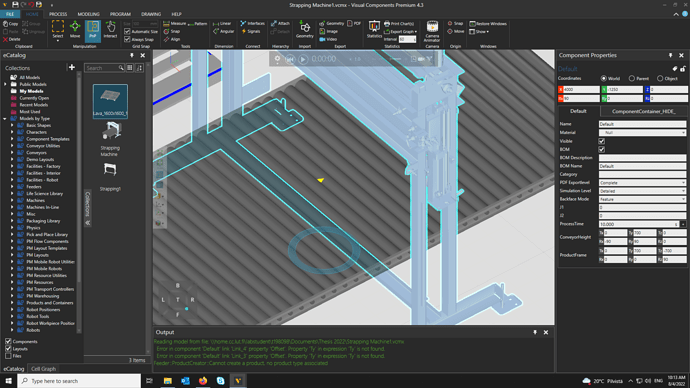

I have changed that and it appears to become an error and the process does not function. From the error message, I think I should fill in some parameters of 2 products. Do you know where can I fix this?

In addition, if the process can operate after this error, I am not sure how the TransportIn statement can stop the product when it reaches certain point where some movements from the machine have to occur before the ChangeType statement so that the operation can look more realistic?

Hi @thanhh019 ,

I am not sure about the error. Would you be able to share this file?

The TransportIn statement will stop the product like on a process node. You could adjust the frame which product stop at to your desired position. Maybe this test file will give you some idea.

test.vcmx (233.2 KB)

Hello,

Here is the file. Unfortunately, it seems that I cannot open your file as it said yours is the newer version: " Component or layout file is newer than application."

Strapping Machine1.vcmx (8.0 MB)

Hi @thanhh019 ,

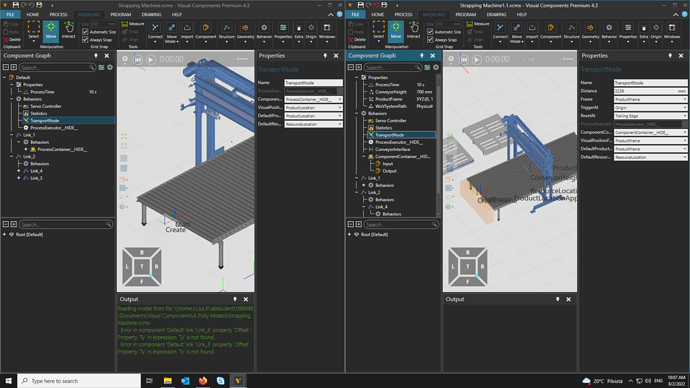

I added some behaviours to your machine and now the TransportIn statement can work properly.

There are 2 new properties too to adjust with the conveyor height and product stopping position.

One small issue, you would need to drag the machine out and connect to conveyor again for the product stopping position to update if you change it.

Strapping Machine1.1.vcmx (8.0 MB)

1 Like

Hi,

Thank you very much. It works now. But can I ask you how can you connect the machine to the feeder and why we need to declare the conveyor height?

In addition, I cannot change the orientation of the machine because originally, the machine cannot stand on the conveyor. Is there way to fix this?

Hi @thanhh019 ,

There is a small error from the previous file, use this file instead:

Strapping Machine1.1.vcmx (8.0 MB)

Edit: updated so that machine can only edit the product stop position if it is detach from conveyor

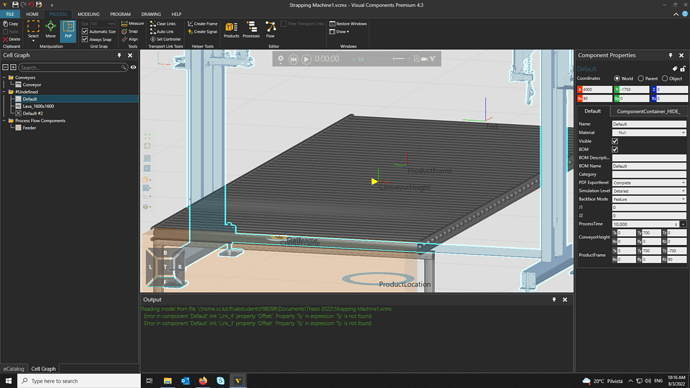

The concept is similar as a Process Node. With the behaviours, it acts like a Process Node that you can attach to conveyor. The “ConveyorHeight” is just a frame name I gave.

1 Like

Hello,

I do not know what to say more than I appreciate your help sincerely. Thank you so much for not feeling this annoying. I hope I did not irritate you. If yes, I am sorry as I am sometimes confused and want know clearly how something operates.

However, since this project is quite big for me and I have to write a report about it while I am still understanding it. I would like to ask you some more questions about how you adjust the process so that i works. I hope you do not mind.

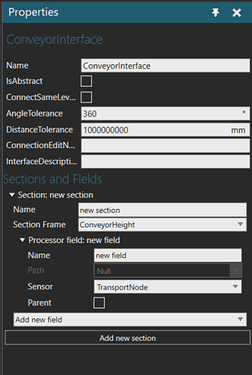

- Are there differences between frame type of “ConveyorHeight” and “ProductFrame” as I do not understand why we cannot use the same type here?

- What is the usage of “WoVSystemPath” string?

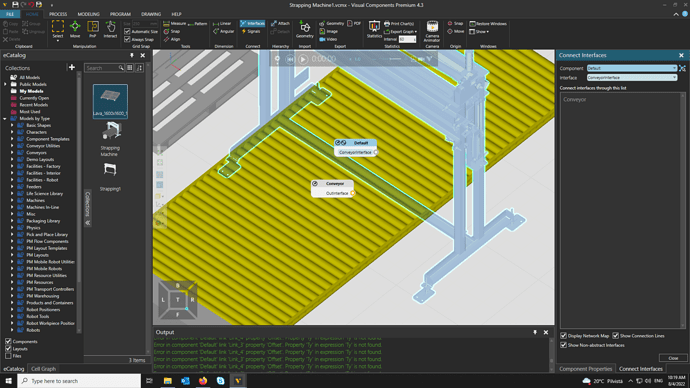

- How can you modify the TransportNode behavior to have the distance and frame stuff? (picture below)

Hi @thanhh019 ,

To answer your questions:

-

The ConveyorHeight is used to position and attach the machine to the conveyor. It works similarly to the MainFrame of a Process Node. I used the ProdcutFrame to adjust the stopping position of the product.

-

This property is automatically generated when I opened the file in different VC version, you can delete it as it does not affect the simulation.

-

That section appears when there is a connection to conveyor. If you detach the machine from conveyor, the TransportNode behaviour will show default properties.

1 Like

Hi,

Thank you very much. I am starting to understand a bit more. However, why can’t I connect the interface from my machine to SensorInterface of the conveyor? I don’t know but it does not show the list from the machine at the time I want to connect interfaces between conveyor and machine together.

Hi @thanhh019 ,

I am not sure about your question.

You do not need to connect them through the interface function. The machine is connected through PnP tool.

Hello,

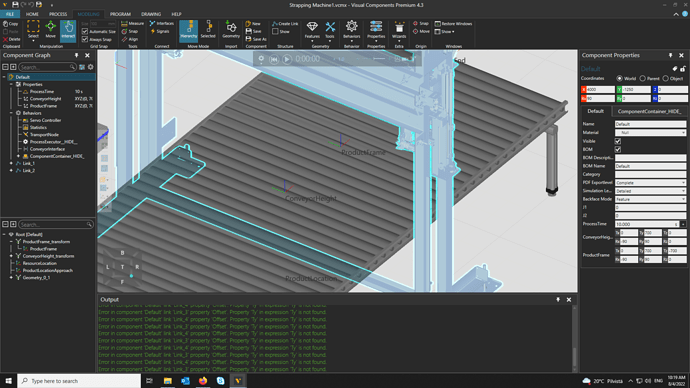

Now I understand the problem but I do not why my PnP mark appears like this, 90° perpendicular to the conveyor. How can I change this so that it can be connected with the conveyor?

Hi @thanhh019 ,

You need to position the frame in which the z-axis (blue) is pointing upwards and x-axis (red) is pointing towards the direction you desired.

2 Likes

Hi,

I have change the coordination but it cannot connect with the SensorInterface as well as PnP with the input side of the conveyor.

Hi @thanhh019 ,

I am confused. Why do you need to do that?

The ConveyorInterface behaviour is there so that it can attach to the conveyor with PnP tool.

Did you configure the ConveyorInterface properly as shown below?

2 Likes