hi, im having issues with my process flow. i am trying to make it loop so when both pallets get to the sink process, two new pallets get created and the cycle repeats. first time i run the simulation the red container pallet is picked up first but then when the second cycle starts, the other pallet is picked up first. both feeder processes are in the same exact spot and set the same time interval for creating products. how can i make it pick up the red container pallet first every time?

workflow - Copy.vcmx (8.1 MB)

Hi,

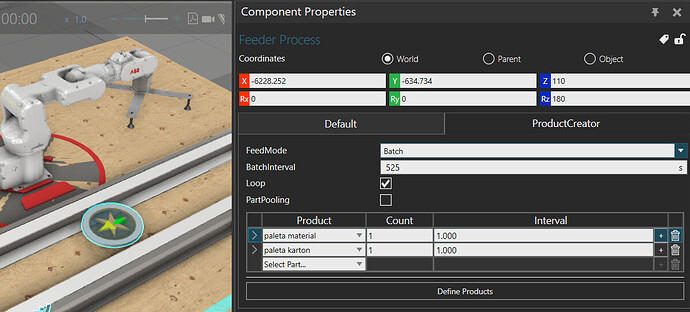

instead of using 2 Feeder one above the other, which is not very practical, you could use just one Feeder with a Batch FeedMode:

how do i make it so the pallets spawn once and then dont spawn again until one cycle is done. (around 525 seconds to complete one cycle).

ive adjusted the workflow and the robot programs to all go from one feeder:

workflow - Copy.vcmx (8.7 MB)

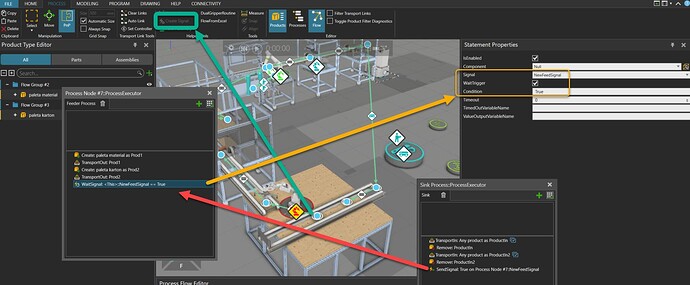

instead of using a Feeder Process, you could use a standard Process Node with Create statements and add a signal to communicate with the Sink process → when the sink receives 2 products, it sends a signal to the Feeder/Process Node, which can then create the 2 pallets again

so i did as you showed me and also adjusted the custom robot program in the ABB robot. now i am having issues with the first stopper not stopping the first pallet when the cycle repeats. and the second pallet does not get transported from “process #2” back to the conveyor. any ideas?

workflow - Copy.vcmx (11.8 MB)

ive been playing around with resetting the stopper signals every cycle and been trying to adjust the python script of the stopper using chat gpt but still no luck. i have no idea why this is happening, considering that everything works normally the first time