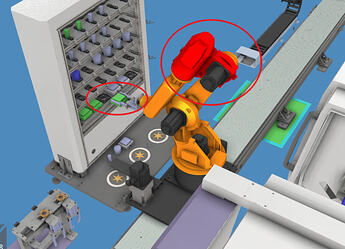

I am using a process flow to implement the robot’s pick-and-place operation on a workpiece rack, with the robot mounted on a guide rail. Currently, I am encountering an issue: when picking and placing workpieces, the robot always directly faces the target point. However, due to the close distance between the workpiece rack and the robot, an axis limit alarm occurs during the robot’s execution of actions, as shown in Figure 1.

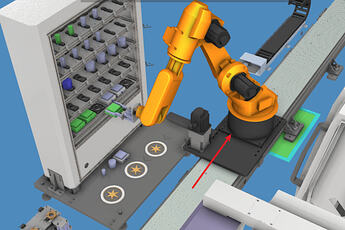

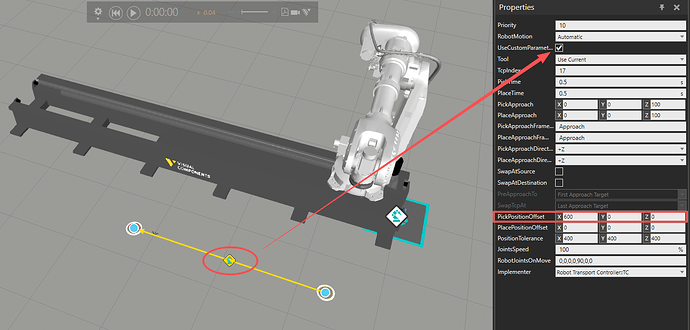

If I were to manually program the robot, I would make the robot first move to the side of the pick-and-place target point, similar to the approach shown in Figure 2, before performing the pick-and-place operation. This would help avoid the limit problem. However, the current transfer controller (or process flow simulation) does not seem to offer such an offset setting. Could anyone provide a solution? The premise is not to move the equipment.