Hi,

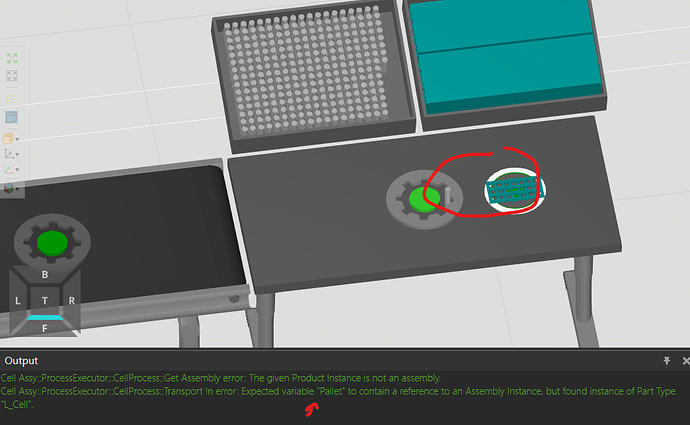

I created a simple assembly and attempted to set up an assembly line simulation, but it doesn’t work. I copied the examples from the Academy one by one, but it still doesn’t work.

K1.vcmx (1.6 MB)

Hi,

Made some changes on the Process tabs.

K1.vcmx (1.6 MB)

Hi Norte,

It works beautifully, but I still don’t understand why it doesn’t work as an assembly without signals and count control, as shown in the example below in the academy.

How to complete an Assembly or Disassembly Task | Visual Components Academy.

Hi,

The video is unavailable.

My model Manual Workstation doesn’t have Signal Capability, but the Norte model has.

https://youtu.be/jourtlaplNg?si=gQfUPiAzkiNsuBr1 Please follow up this vdo slowly step by step

My guess is that it is because you are transporting in pieces from two different proces nodes, thats why, even though you get the assembly, is transporting in whatever it is ready to do so. Thats why I use signals, to order the transport outs.

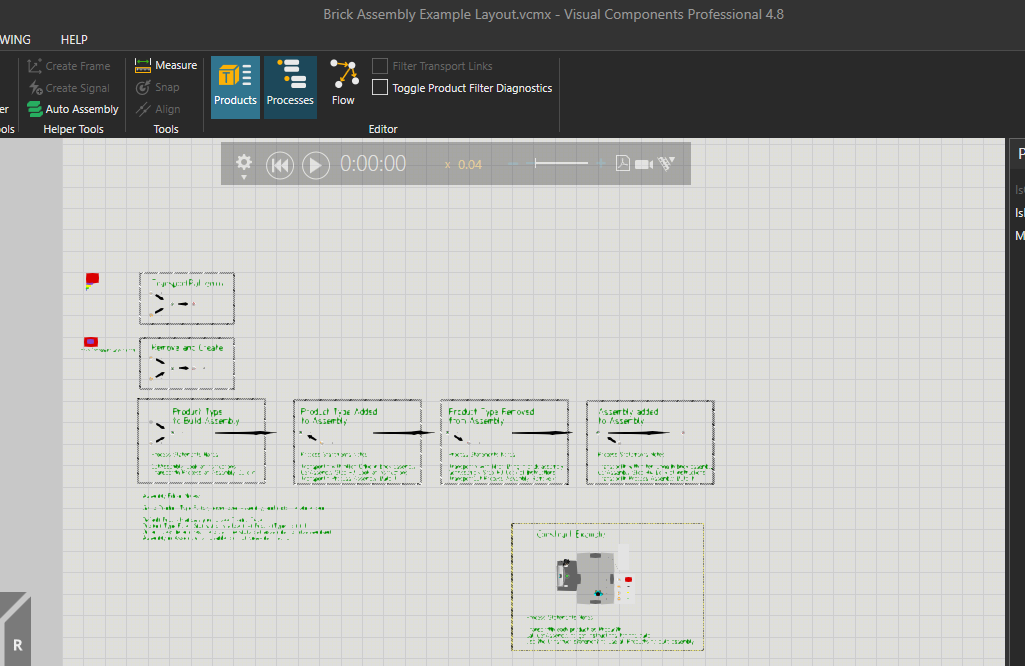

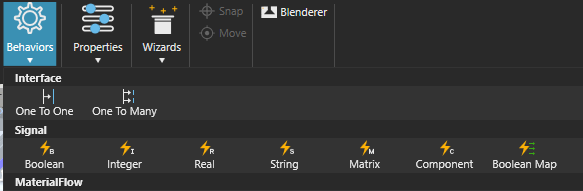

You can create signals from the modeling tab manually:

Or, from the process tab, there is this option:

![]()

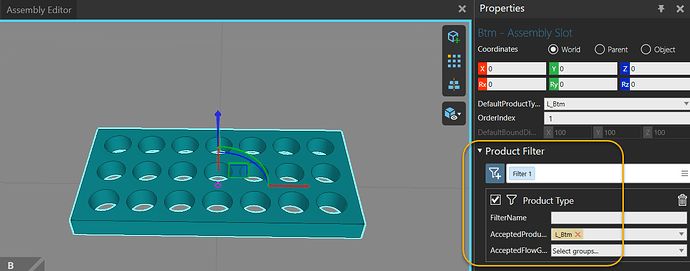

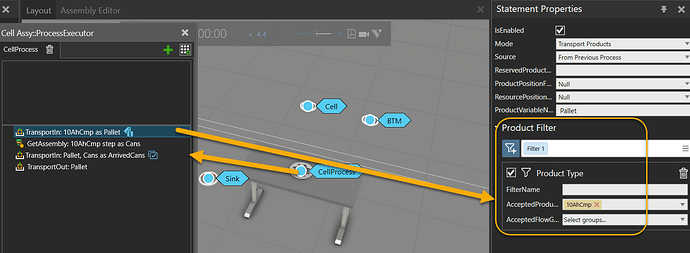

You don’t need to use signals, but you should use the Product filters:

-

in your assembly editor, to define what can be assembled in which slot :

-

in your CellProcess for the first TransportIn : this way you can say that the product coming in at the beginning is your assembly (with just the Btm step)

in the Academy video, the pallet comes from the conveyor, so the first TransportIn has it Source defined as “From Component Container”, which in this case can only be the conveyor, that’s why there was no product filter used

I’ve done, it didn’t work.

That’s what I got : K1_2.vcmx (1.6 MB)

It works perfectly and simply! I got what is missed. Thank you so much.