Hello everyone! Has anyone know how to model a sensor that can detect the position of an axis. For example when the axis moves to 50 the sensor will output 1 and everywhere else the sensor outputs 0. Thanks!!!

Hello,

I don’t quite understand what you mean. If you need to trigger at a specific position, you can use the ray sensor, volume sensor, and path sensor in the modeling. In my opinion, every sensor can be used to solve your problem.

Hope that’s what you’re thinking of, have a nice day.

Also attach the material of the Visual Components Academy

EventHandlersEnd.vcmx (156.9 KB)

Hi, BAD it’s you again! You are really great, thank you. I’m trying to finish with a ray sensor. I would like to ask about process modeling by the way. Let’s say there are three bottles that are transported to the conveyor belt by the robot, I want to implement them in a specific sequence, for example by 1-2-3, but now it’s 3-2-1, I modified the priority in Flow but it doesn’t seem to work at all. Can you help me?

Hello Miao Wentao,

Glad the previous replies were helpful, as for your new question about executing in a specific order, I saw the conveyor belt in your question so I made a demo.

first in first out.vcmx (1.1 MB)

If that’s what you want, then it’s not a problem with the “PROCESS” function, it’s a problem with the “MODELING” function. In fact, to account for congestion, the conveyor belt uses a “SpaceUtilization” property, which is located in the conveyor belt’s path behavior. The main purpose of this property is to disable “overtaking” of overlapping components on the conveyor belt, that is, it will disturb the output order of overlapping components on the conveyor belt. Turn it off and things should work as you expect.

Hope it helps you.

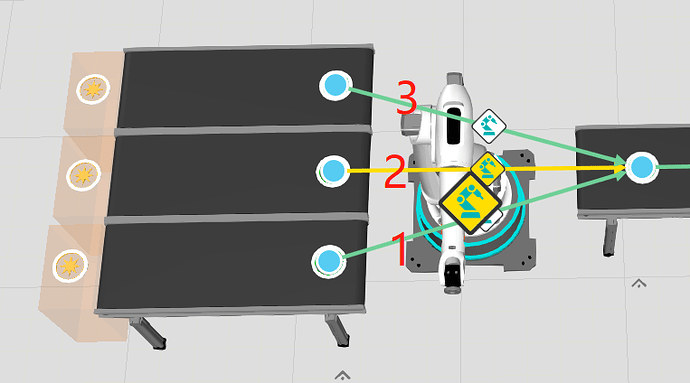

Good morning BAD, thanks for your reply, but I don’t seem to mean that. Do you know how to modify the sequence of the robot carry components in the order shown in the picture?

Ummm, based on my current knowledge, it seems impossible to directly change these orders, and changing them requires certain conditions to be constrained. As for the Priority attribute, it seems to be used for the priority level between multiple controllers, not the priority of a single actuator behavior, so changing it here will not affect the order of execution.

The simpler way I can think of at present is to change the order of accepting product types in the Process of the output conveyor belt to achieve a change in the grabbing order.Attached is my modified version.

FIFO.vcmx (1.2 MB)

Hope this idea helps you, and that you can find a better way!

Okay, thanks for your reply, you’re really so friendly! Hope you have a nice day!