Hi Visual Components Forum,

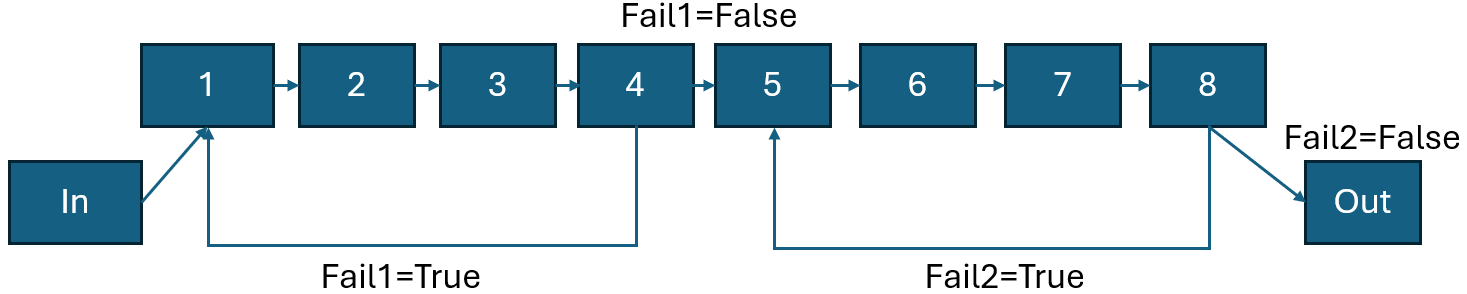

I’m currently building a layout of a production-line with a lot of manual processes. In the line of processes there are two stations where fails on the product can happen. IF fails happens on the products in these steps, the product needs to be taken from the present module and back to another module further back in the line and go through the same processes again. My question is, how will I do that with the standard process modelling?

I have seen in other posts on the forum that some uses filters to control the “split“ of good/bad products to different stations (parallel processes), but my challenge is that I need to send the product back in the production process based on failure state and I can’t seem to think of any obvious solutions to this. I have implemented product properties where the fail is written to and the logic behind statistically assigning fails to products based on specific failrate

I have attached example of how the overview looks like.

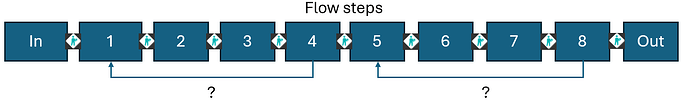

I have tried to setup my flowsteps in different configurations to make this happen, but without luck. I should add that I want it to be the same product because I am also monitoring the leadtime of the product. I know I could be creating a new product based on failures and send them back the line to go through processes again - and I will do this if I do not find a solution on how to do it with the “original“ product.