Additional information:

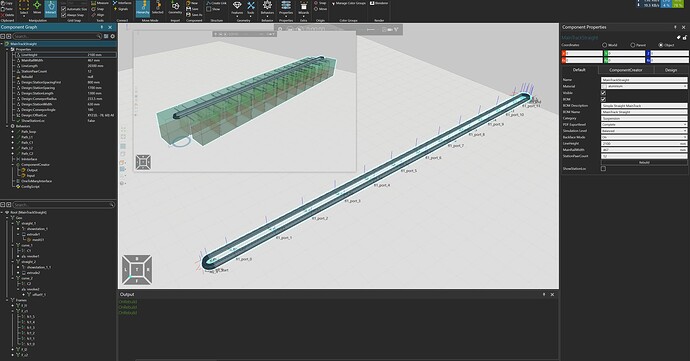

1. Modeling Background Statement:

I am engaged in modeling for the garment industry’s hanging system, which is a crucial component of modern manufacturing processes in clothing production. This system primarily comprises a main track (conveyor line) and branch tracks (intra-station tracks, entry and exit stations, and lifting mechanisms). The current objective is to model the main track conveyor line, which serves as the backbone for the efficient transportation of garments throughout the production cycle.

2. Introduction to the Main Track Conveyor System:

The main track conveyor system is a vital part of the intelligent hanger system used in the garment industry. It is designed to enhance the efficiency and automation of the production line. Here’s an overview of its components and functionality:

Usage : The main track is primarily utilized for the transportation and circulation of hangers. Through the intelligent hanging control system, hangers are transported to corresponding stations where specific operations are performed. This system significantly reduces downtime associated with manual handling, bundling, and folding, streamlining the production process.

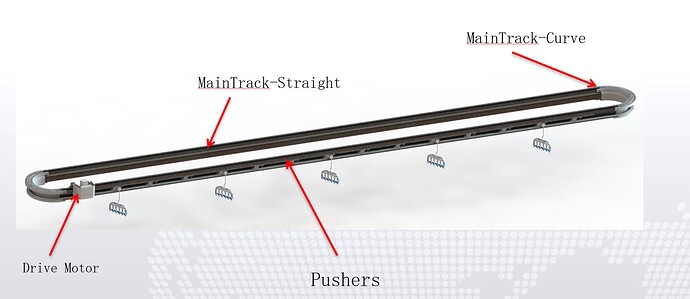

- Components:

- Closed Track Sequence: The main track forms a continuous loop consisting of various straight tracks and bends, allowing for a seamless and unidirectional flow of hangers.

- Racks/Chains: These are part of a closed system that moves in synchronization around the main track body, driven by a motorized driver to ensure consistent motion.

- Pushers: Equally spaced along the chains, pushers are responsible for propelling hangers forward at regular intervals.

- Drivers: These are the motors or mechanical devices that provide the的动力 to the system, ensuring the coordinated movement of the chains and pushers.

Modeling Objectives in Visual Components:

In Visual Components, I aim to achieve a sophisticated modeling goal for the garment industry’s conveyor system, which involves creating a dynamic and adaptable main track for the intelligent hanger system. The envisioned system will have the following features:

Flexible and Free Combination of Main Track Shapes:

A main track that can be freely shaped and combined, not confined to basic straight lines but capable of incorporating multiple turns, ascents, and descents to form a multi-tiered, three-dimensional track structure. This design allows for easy, ground-based assembly and quick interconnection of track sections.

The future capability to define the track’s path through a series of configuration commands, which could include straightforward movements and turns, such as moving straight for a certain distance, making a sharp left turn, or ascending at a specific angle over a set distance. such as “straight 100 units, left turn 180 degrees, straight 200 units, ascend at a 30-degree angle for 10 units,” etc.

Unified Control for Generation and Driving of the Pusher System:

A unified control system for the generation and propulsion of the pusher system, which will be responsible for the synchronized movement of pushers along the main track, ensuring the efficient transfer of hangers to their designated stations.

Separation and Propulsion of Hangers on the Main Track:

Hangers will be separated and propelled by pushers on the main track, allowing for organized and efficient transportation of garments through the production process.

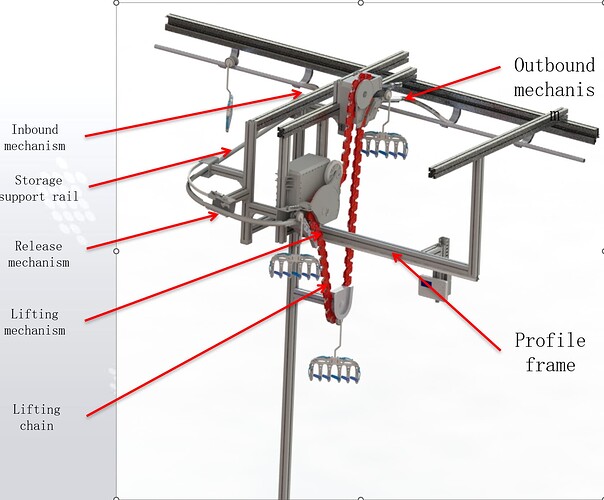

Controlled Entry and Exit of Hangers at Junctions Between Main and Branch Tracks:

Hangers will be controlled at the inlets and outlets where the main track intersects with branch tracks, enabling precise entry into and exit from stations for various operations.

As a novice in the Visual Components community, I have embarked on a journey to learn and explore the process of modeling within this platform. My current efforts, though enthusiastic, are often met with uncertainty and a lack of conceptual clarity.

I am reaching out with genuine intent to seek guidance from seasoned experts within the VC community. I believe that with your expertise and advice, I can navigate the learning curve more effectively and avoid common pitfalls that may arise during the modeling process.

My primary goal is to harness the full potential of VC’s capabilities and integrate its concepts into my projects seamlessly. I am particularly interested in:

- Receiving constructive feedback on my current modeling approaches and any potential improvements.

- Gaining insights into best practices for leveraging VC’s features to their fullest extent.

As I navigate the modeling process in Visual Components, I am particularly interested in receiving constructive feedback on my approaches, especially regarding the integration of main tracks with branch tracks for station positions. Here are some specific areas where I am seeking guidance and potential improvements:

PNP (Pick and Place) Connection with Branch Track Stations:

I am currently unsure about how to effectively establish PNP connections between the main track and branch track stations. Ideally, I would like to be able to drag a station position close to the main track’s port and have it automatically pair and connect the entryStation and exitStation interfaces.

Automated Instantiation and Connection Along the Main Track:

I envision a more advanced scenario where, given a specified branch track component, setting the number of station positions on the main track would automatically instantiate and connect station components along the straight sections of the main track. This would streamline the process and reduce manual setup. Same as StationPlaceholder in ShowStationLoc

I am eager to engage with the community, share my progress, and contribute to the collective knowledge base. I am confident that with the right guidance, I can enhance my skills and contribute meaningfully to the VC ecosystem.

Thank you for considering my request for mentorship and support. I look forward to a fruitful and enlightening exchange with the community.