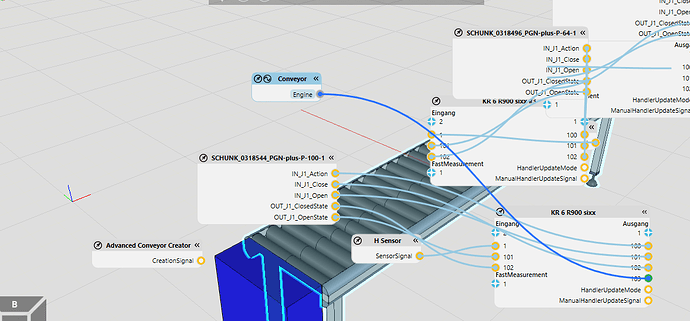

Here it is in tekst and in picture, i’ve also included the document at the end

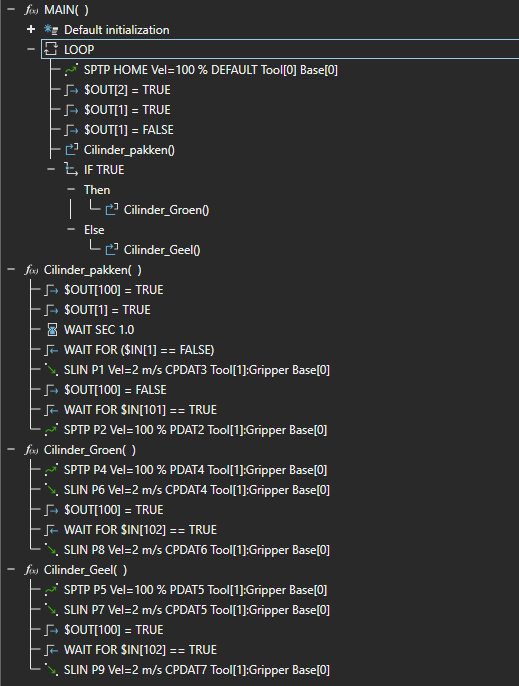

DEF MAIN()

;FOLD INI;%{PE}

;FOLD BASISTECH INI

GLOBAL INTERRUPT DECL 3 WHEN $STOPMESS == TRUE DO IR_STOPM()

INTERRUPT ON 3

BAS(#INITMOV, 0)

;ENDFOLD (BASISTECH INI)

;FOLD USER INI

;Make your modifications here

;ENDFOLD (USER INI)

;ENDFOLD (INI)

LOOP

;FOLD SPTP HOME Vel=100 % DEFAULT Tool[0] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=HOME; Kuka.BlendingEnabled=False; Kuka.MoveDataPtpName=DEFAULT; Kuka.VelocityPtp=100; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SPTP; SimId=

;ENDFOLD

SPTP XHOME WITH $VEL_AXIS[1] = SVEL_JOINT(100.0), $TOOL = STOOL2(FHOME), $BASE = SBASE(FHOME.BASE_NO), $IPO_MODE = SIPO_MODE(FHOME.IPO_FRAME), $LOAD = SLOAD(FHOME.TOOL_NO), $ACC_AXIS[1] = SACC_JOINT(PDEFAULT), $APO = SAPO_PTP(PDEFAULT), $GEAR_JERK[1] = SGEAR_JERK(PDEFAULT), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

$OUT[2] = TRUE

$OUT[1] = TRUE

$OUT[1] = FALSE

Cilinder_pakken()

IF TRUE THEN

Cilinder_Groen()

ELSE

Cilinder_Geel()

ENDIF

ENDLOOP

END

DEF Cilinder_pakken()

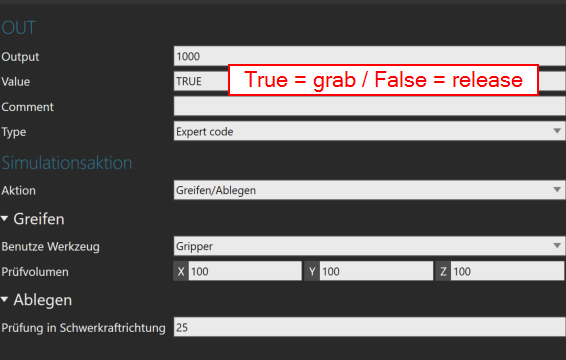

$OUT[100] = TRUE

$OUT[1] = TRUE

WAIT SEC 1.0

WAIT FOR ($IN[1] == FALSE)

;FOLD SLIN P1 Vel=2 m/s CPDAT3 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P1; Kuka.BlendingEnabled=False; Kuka.MoveDataName=CPDAT3; Kuka.VelocityPath=2; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SLIN; SimId=

;ENDFOLD

SLIN XP1 WITH $VEL = SVEL_CP(2.0, , LCPDAT3), $TOOL = STOOL2(FP1), $BASE = SBASE(FP1.BASE_NO), $IPO_MODE = SIPO_MODE(FP1.IPO_FRAME), $LOAD = SLOAD(FP1.TOOL_NO), $ACC = SACC_CP(LCPDAT3), $ORI_TYPE = SORI_TYP(LCPDAT3), $APO = SAPO(LCPDAT3), $JERK = SJERK(LCPDAT3), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

$OUT[100] = FALSE

WAIT FOR $IN[101] == TRUE

;FOLD SPTP P2 Vel=100 % PDAT2 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P2; Kuka.BlendingEnabled=False; Kuka.MoveDataPtpName=PDAT2; Kuka.VelocityPtp=100; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SPTP; SimId=

;ENDFOLD

SPTP XP2 WITH $VEL_AXIS[1] = SVEL_JOINT(100.0), $TOOL = STOOL2(FP2), $BASE = SBASE(FP2.BASE_NO), $IPO_MODE = SIPO_MODE(FP2.IPO_FRAME), $LOAD = SLOAD(FP2.TOOL_NO), $ACC_AXIS[1] = SACC_JOINT(PPDAT2), $APO = SAPO_PTP(PPDAT2), $GEAR_JERK[1] = SGEAR_JERK(PPDAT2), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

END

DEF Cilinder_Groen()

;FOLD SPTP P4 Vel=100 % PDAT4 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P4; Kuka.BlendingEnabled=False; Kuka.MoveDataPtpName=PDAT4; Kuka.VelocityPtp=100; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SPTP; SimId=

;ENDFOLD

SPTP XP4 WITH $VEL_AXIS[1] = SVEL_JOINT(100.0), $TOOL = STOOL2(FP4), $BASE = SBASE(FP4.BASE_NO), $IPO_MODE = SIPO_MODE(FP4.IPO_FRAME), $LOAD = SLOAD(FP4.TOOL_NO), $ACC_AXIS[1] = SACC_JOINT(PPDAT4), $APO = SAPO_PTP(PPDAT4), $GEAR_JERK[1] = SGEAR_JERK(PPDAT4), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

;FOLD SLIN P6 Vel=2 m/s CPDAT4 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P6; Kuka.BlendingEnabled=False; Kuka.MoveDataName=CPDAT4; Kuka.VelocityPath=2; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SLIN; SimId=

;ENDFOLD

SLIN XP6 WITH $VEL = SVEL_CP(2.0, , LCPDAT4), $TOOL = STOOL2(FP6), $BASE = SBASE(FP6.BASE_NO), $IPO_MODE = SIPO_MODE(FP6.IPO_FRAME), $LOAD = SLOAD(FP6.TOOL_NO), $ACC = SACC_CP(LCPDAT4), $ORI_TYPE = SORI_TYP(LCPDAT4), $APO = SAPO(LCPDAT4), $JERK = SJERK(LCPDAT4), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

$OUT[100] = TRUE

WAIT FOR $IN[102] == TRUE

;FOLD SLIN P8 Vel=2 m/s CPDAT6 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P8; Kuka.BlendingEnabled=False; Kuka.MoveDataName=CPDAT6; Kuka.VelocityPath=2; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SLIN; SimId=

;ENDFOLD

SLIN XP8 WITH $VEL = SVEL_CP(2.0, , LCPDAT6), $TOOL = STOOL2(FP8), $BASE = SBASE(FP8.BASE_NO), $IPO_MODE = SIPO_MODE(FP8.IPO_FRAME), $LOAD = SLOAD(FP8.TOOL_NO), $ACC = SACC_CP(LCPDAT6), $ORI_TYPE = SORI_TYP(LCPDAT6), $APO = SAPO(LCPDAT6), $JERK = SJERK(LCPDAT6), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

END

DEF Cilinder_Geel()

;FOLD SPTP P5 Vel=100 % PDAT5 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P5; Kuka.BlendingEnabled=False; Kuka.MoveDataPtpName=PDAT5; Kuka.VelocityPtp=100; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SPTP; SimId=

;ENDFOLD

SPTP XP5 WITH $VEL_AXIS[1] = SVEL_JOINT(100.0), $TOOL = STOOL2(FP5), $BASE = SBASE(FP5.BASE_NO), $IPO_MODE = SIPO_MODE(FP5.IPO_FRAME), $LOAD = SLOAD(FP5.TOOL_NO), $ACC_AXIS[1] = SACC_JOINT(PPDAT5), $APO = SAPO_PTP(PPDAT5), $GEAR_JERK[1] = SGEAR_JERK(PPDAT5), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

;FOLD SLIN P7 Vel=2 m/s CPDAT5 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P7; Kuka.BlendingEnabled=False; Kuka.MoveDataName=CPDAT5; Kuka.VelocityPath=2; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SLIN; SimId=

;ENDFOLD

SLIN XP7 WITH $VEL = SVEL_CP(2.0, , LCPDAT5), $TOOL = STOOL2(FP7), $BASE = SBASE(FP7.BASE_NO), $IPO_MODE = SIPO_MODE(FP7.IPO_FRAME), $LOAD = SLOAD(FP7.TOOL_NO), $ACC = SACC_CP(LCPDAT5), $ORI_TYPE = SORI_TYP(LCPDAT5), $APO = SAPO(LCPDAT5), $JERK = SJERK(LCPDAT5), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

$OUT[100] = TRUE

WAIT FOR $IN[102] == TRUE

;FOLD SLIN P9 Vel=2 m/s CPDAT7 Tool[1]:TOOL_DATA[1] Base[0] ;%{PE}

;FOLD Parameters ;%{h}

;Params IlfProvider=kukaroboter.basistech.inlineforms.movement.spline; Kuka.IsGlobalPoint=False; Kuka.PointName=P9; Kuka.BlendingEnabled=False; Kuka.MoveDataName=CPDAT7; Kuka.VelocityPath=2; Kuka.VelocityFieldEnabled=True; Kuka.ColDetectFieldEnabled=True; Kuka.CurrentCDSetIndex=0; Kuka.MovementParameterFieldEnabled=True; IlfCommand=SLIN; SimId=

;ENDFOLD

SLIN XP9 WITH $VEL = SVEL_CP(2.0, , LCPDAT7), $TOOL = STOOL2(FP9), $BASE = SBASE(FP9.BASE_NO), $IPO_MODE = SIPO_MODE(FP9.IPO_FRAME), $LOAD = SLOAD(FP9.TOOL_NO), $ACC = SACC_CP(LCPDAT7), $ORI_TYPE = SORI_TYP(LCPDAT7), $APO = SAPO(LCPDAT7), $JERK = SJERK(LCPDAT7), $COLLMON_TOL_PRO[1] = USE_CM_PRO_VALUES(0)

;ENDFOLD

END

case robotica.vcmx (3.1 MB)