I’ve recently been learning the parts of using OLP for welding, which I’m not particularly familiar with, and I’m learning by following along with the videos in the academy, and I’ve noticed a strange problem.

The first chapter I’m learning is about setting up and checking weld paths, and after I followed along, I strangely realized that the path checking was already 100% passed, but when I ran it, it still collided, which is strange isn’t it? It doesn’t make sense that it should be like this after I’ve processed it and the path check is ok, am I doing something wrong?

Would appreciate a reply from anyone and thanks in advance!

Attached is a video:

Without the layout we can only guess, but are you sure the correct detector is used by the path check tool?

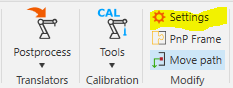

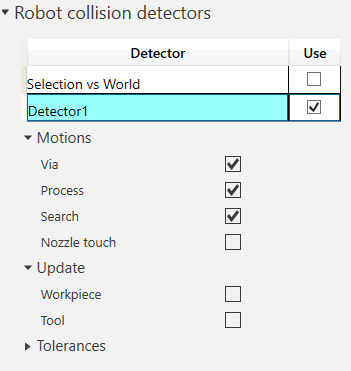

If you open the robot settings (in Program tab, yellow gear, right next to the Cal tools), then setup→Robot collision detectors. That is where you tell the path check tool what detector to use, and when.

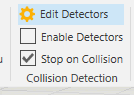

You need to make sure that the detector that is being used is the correct one. You can check your detectors by clicking on “Edit Detectors” in Program tab.

After making sure that the correct detector is being used, you need to put a check mark in the motion types in which you want the detector to be used by the check path tool. (Choices are :Via, Process, Search, Nozzle touch). The point is that you can use different detectors for different motions. For example, a detector that excludes the welding wire for process statements (during welding), and another that includes the wire for via statements (air cuts).

As I said in my reply at the beginning, my learning process was through the Academy’s materials, and the models were from the official VC offerings, from this link:

Regarding your question about colliders, as far as I’m concerned, there shouldn’t be a problem, because the colliders in the model I checked, and the VC should have all been set up officially for that.

Because I got an error report for uploading the model (not quite sure what happened), to add to that, I did exactly what the video in the link said, set up the weld path, enabled the collision detector, checked it, manually adjusted it, checked it again, and the next thing you know, that’s where my problem came in.

I tested the layout from your link. Everything seems fine, and the path check tool correctly detected every collision (including during searches, where the problem happened on your side).

So I don’t know why that happened on your side, if you try again fresh with the model from the tutorial it should work. There is no need to adjust any setting, it’s all set up correctly already (only need to enable detectors to see collisions in the simulation)

I’ll go ahead and try to reproduce the problem, but I want to emphasize that this one video of an OLP soldering primer, I did exactly what he said to do, I did nothing else extra, and in this case’s, with this problem, I may have to put a “?” to OLP’s credibility.

Rather surprisingly, the error came sooner than I thought, I found the general problem, some collision events, it will somehow disappear, and reply to me that “here is OK now”, the video is as follows:

Seems to be working, great!