Hi guys,

I have a simulation program on KUKA.SIM PRO 3.1 which is a spot welding application with a KR210 R3100-2 robot.

It’s my first time with welding application. I’m here on the field to commision the robot and I believe that I need a better tool values.

So It will be my first time to take the tool values right from the simulation.

My question is what are the steps to get the right tool values from the simulation and put to the robot on the field.

Thanks in advence…

Hi Yigit,

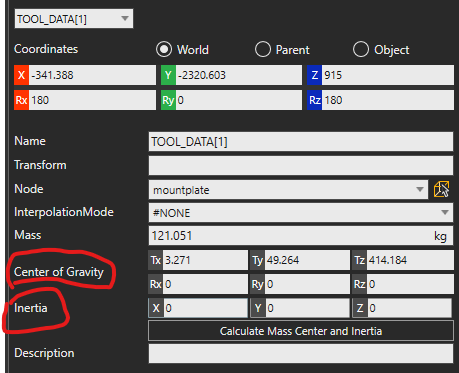

As KUKA.Sim Pro 3.1 is no longer supported, I can only try to help you with KUKA.Sim 4.X. If you are referring to the load data in KUKA.Sim eg

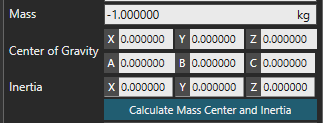

please enter the values from your CAD program.

In KUKA.Sim 4.X the RCS System will take into account the mass, center of gravity and inertia and adapt the speed of the robot and thus the cycle times. (This will not be the case for KUKA.Sim 3)

If you use the “Calculate Mass Center and Inertia” button, it will use the information from inside KUKA.Sim, so it will be very dependent on the materials and the level of detail that you used in Modeling. I always strongly recommend not to use the button, as the calculated values are mostly wrong.

Please re-calculate and validate the load data before transferring the information onto a real robot (whether it comes from the CAD program or KUKA.Sim)! And use KUKA.Load to validate your setup!

Hi!Friends! I need your help!

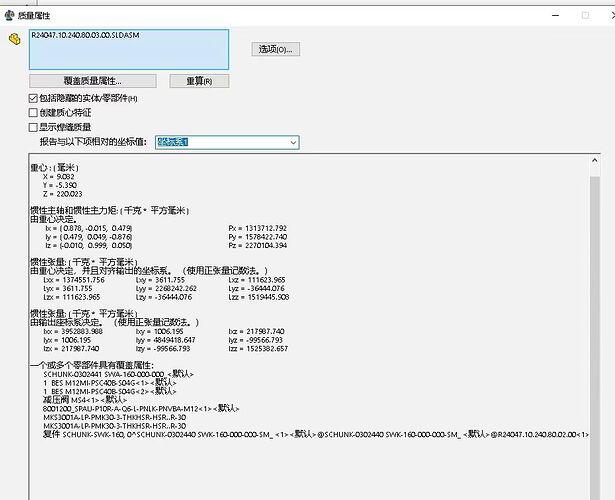

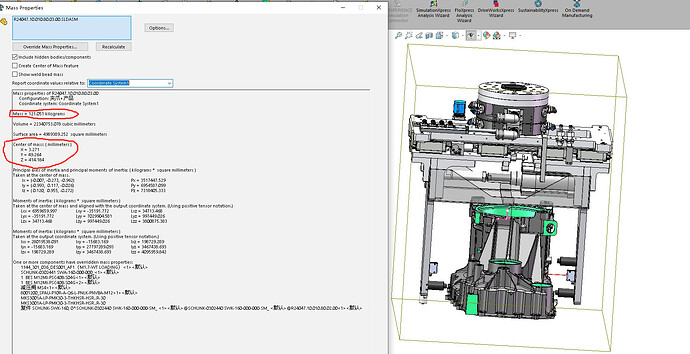

First, how do you calculate the inertia in this VC then? There is a difference between the inertia calculated mechanically with Solidworks and the inertia settings in VC.

Second, the robot’s center of gravity changes during high-speed movement; in the VC simulation software, I wonder if this center of gravity also changes when the KUKA robot is running?

Please use the values you get from Solidworks. As said above, the calculated inertia from VC is not very accurate.

When you enter the inertia, the KUKA robot will adapt it’s speed if you are using the RCS module in VC with the KUKA.Sim AddOn.

Hi!Friends! I still face some challenges! I need your help!

First, in the data provided by Solidworks for machinery, there are weight and center of gravity. How do I fill in the Rx, Ry, Rz options for Center of Gravity in VC.

Secondly, Solidworks provides a lot of inertia data for machinery, but the only inertia inputs in VC are XYZ. How do I fill in the inertia data provided by machinery in VC, and what kind of inertia data do I fill in? The inertia data provided by the machinery are more than 6, while VC only has 3 inputs for the values.

I would use the principal axes of inertia,

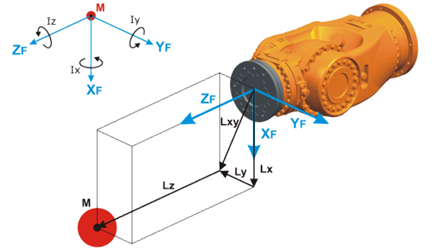

You can use the following image as a reference for the VC / KUKA.Sim Input

Whereas the Inertia needs to be converted in kgm² not kgmm² like in you Solidworks export

Thank you very much!