I have a process where a lathe should make 40 parts from a single 2000 mm long bar stock, created by a feeder process. But I cannot figure out how to do this, and I’ve not been able to find any tutorials. Any tips?

Hy,

maybe try to realize this over “Assemblies”

Regards

I don’t understand how that would work.

So you want for a long part to go in lathe, door closes, delay, door opens, and there are 40 pieces stacked above each other?

Hy,

I thought that the stack is done over assemblies, here a link:

Assembly in processes | Visual Components Academy

Regards

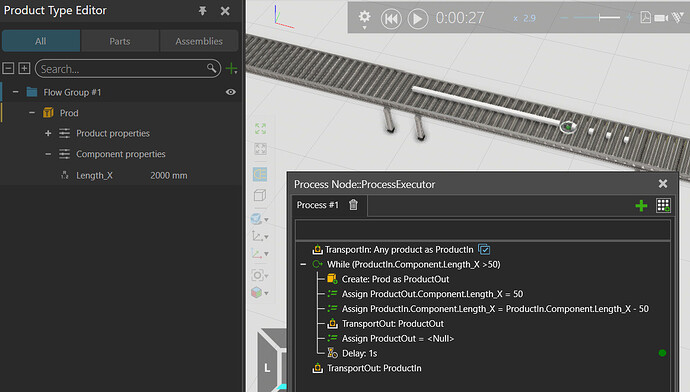

You could use a While loop and Assign statements to reduce the size of the bar each after loop. You need a parametric property for the length though.

Layout_Cutting a product.vcmx (407.1 KB)

Thank you! That’s exaclty what I need. I’ll try modifying my simulation like this.

That is not how lathes work ![]()

A bar stock, 2000 mm lenght of 25 mm steel in this case, is fed into the lathe.

The lathe cuts off a 50 mm piece from the stock, opens the door etc.

There is still 1950 mm of stock left, so there is no need to feed a new 2000 mm long stock, so the cutting process repeats until all of the bar stock is used. THEN a new bar stock is fed in.

I scrolled thought it and I still have no idea how this should be done with assemblies, it even sounds very counter intuitive. Do you mean that I cannot feed in long bar stock, like you would in real life, but instead I need to feed in an assembly, that is made with 40 parts?

Can you share your VC file?

I did the same for sawing machine where it feeds a 6m square beam, and cuts 8 pieces (each around 7000mm as I remember), one piece at a time and transport the part out.

This is what I did:

Before any of the below, you should have two components in the flow group.

A) one for the long part you will feed into lathe to cut, call it “extruded”

B) and another one which is for already cut part that will feed out from lathe, call it “cut”

-

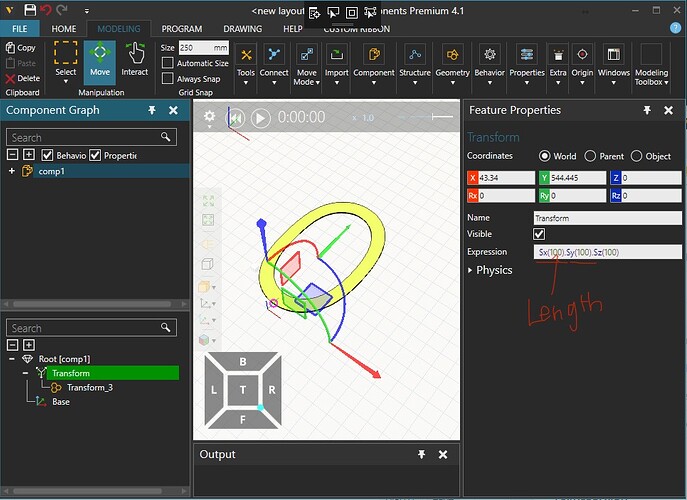

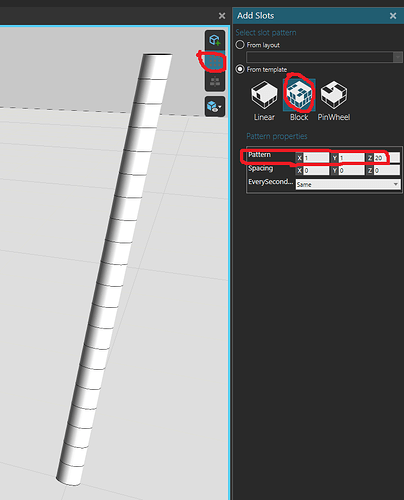

In modeling tab, I added an integer property to the extruded part that I want to cut or machine, I chose “Distance” and called the property “Length”.

-

Then in the component tree of extruded, put the component in a “transform” . ((Check image))

-

In feature properties (on right side of screen), in “Expression” box , write Sx(Length) or Sy(Length), or Sz(Length). try which one is correct to adjust the length of part.

-

Click on extruded part again and you should find a “Length” property . Check if it’s working by changing number.

-

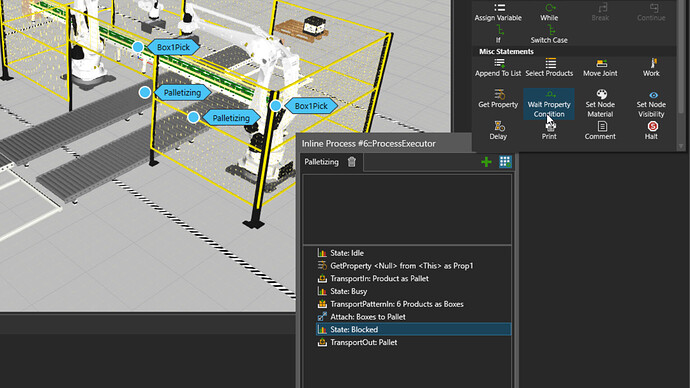

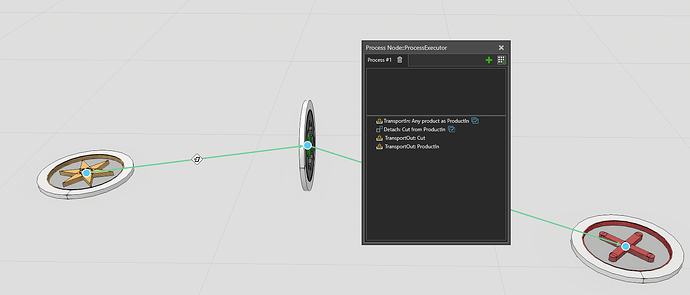

Go to “process” tab, click on a process node , add “get property “, select the extruded component/part you want to cut, and the target property “length”, and property variable name to be “Length”

-

Add “Assign Variable”, TargetProprety “Length” , Value Expression “Length-0.5”. or change it as much as you want to reduce the length of the extruded part at each cut.

-

after the “Assign Variable” line, add a “create” command, choose component cut, and this will be your PartOut

-

copy and paste the lines (or add a loop), until you create 40 cut parts from the extruded part

So what will happen is, it will feed a long extruded part, machine it, the extruded length will reduce, and will create a cut part at the same time, so it will imitate “machining” process.

The it will transport out the cut part