Hi all,

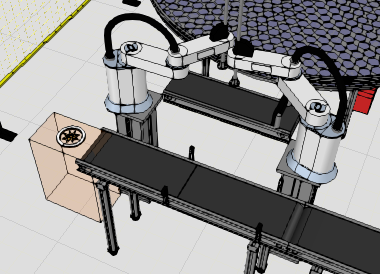

I am trying to build a layout as shown in the screenshot below

as you can see there are 2 robots and two conveyor sensors

i want the products first to stop at the second sensor and the sencond product to stop at the first sensor so that the robots and pick n place the items accordingly

In my case the product getting stopped at the first sensor itself.

second issue is i am not aware how to program two robot which have to pick n place at the same time, if i select one robot and program only it will work but the other one wont work and vice versa plese let me know what i can do in this situation

Hi @Mohammed

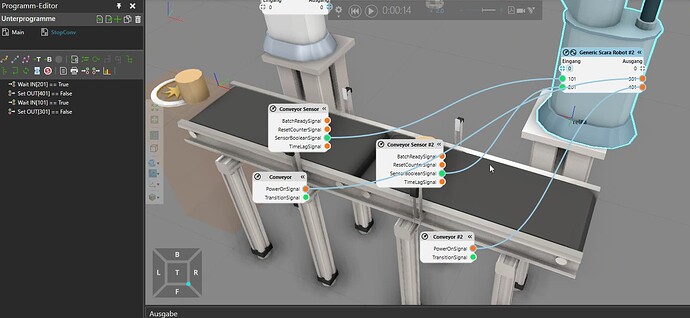

you can use signals to move this logic that you are describing to your robot programs (program tab).

See this Video tutorial on the academy on how to use signals with sensors and conveyors:

As for the second problem: Without more infos I don’t know what is happening.

Hi @cassian315 i know how to connect the signals but not aware how to program them such that 1st box coming out of the conveyor is allowed to pass the 1st sensor undetected and it gets stopped by the second sensor and then when the second fox comes from the feeder it gets stopped by the first feeder and after that the robots can pick and place the objects in the two different boxes stopped at two different sensor positions

Correction - second sensor not feeder

With this setup you can stop two components with the help of the robot program. Notice how I used two conveyors instead of one, to stop the products individually.