Dear

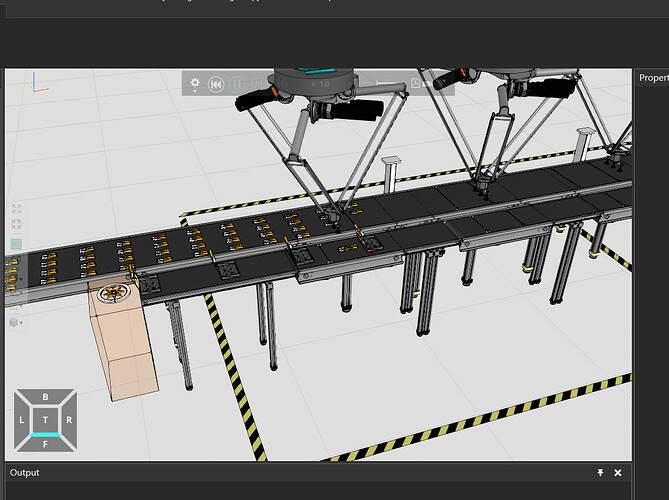

I have created a layout with 4 robots, 1 conveyor to feed the objects, 1 conveyor to feed the trays. I want the robots to pick up the objects and drop them into the tray according to their pre-arranged positions according to the assembly. I have done the robot pick part but I am having problems with the robot dropping them in the tray. Can someone check the program I did and help me figure out why it’s not working?

Thanks a lot

CandyPickingAndPacking - Copy.vcmx (4.4 MB)

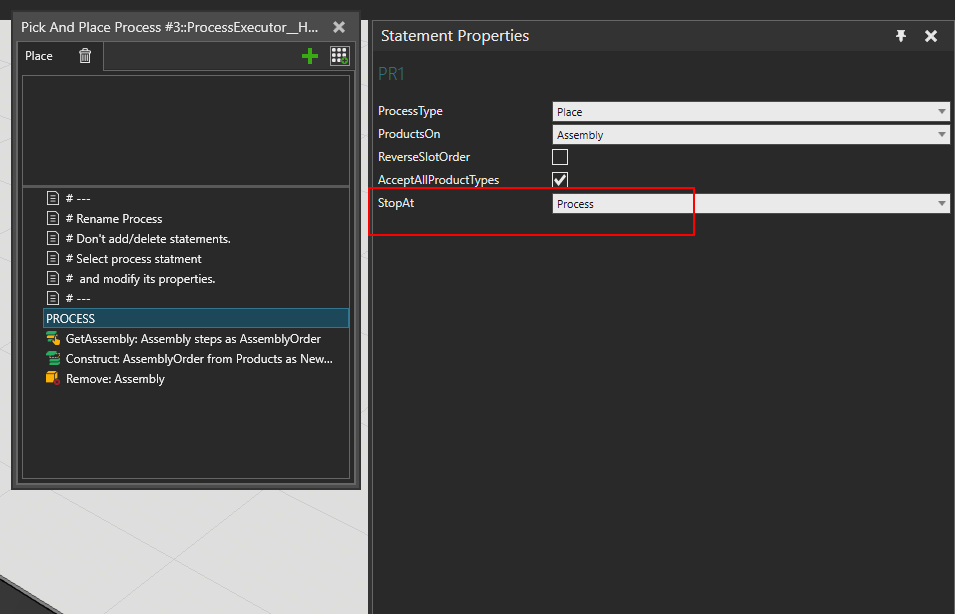

There are few settings that are faulty. On Place processes the process property “ProductsOn” should be “Assembly” as products are placed on an assembly and not directly on conveyor. Another problem was that flow was defined to wrong flow group where products “Choco1” and “Choco2” were not included. And those are the products created on the pick lane. Check the attached model where I made these small fixes. I also tuned the gripper/TCP dimensions and assembly slot order so that multipick pattern matches the tool setup.

CandyPickingAndPacking - Copy v2.vcmx (4.5 MB)

-k

Thank you so much. Let me double check. ^.^

I would like to ask more how to stop the conveyor if the tray is not full. Then restart the conveyor after the tray is full. Thanks a lot

I got it. Thank you so muck

Hi k

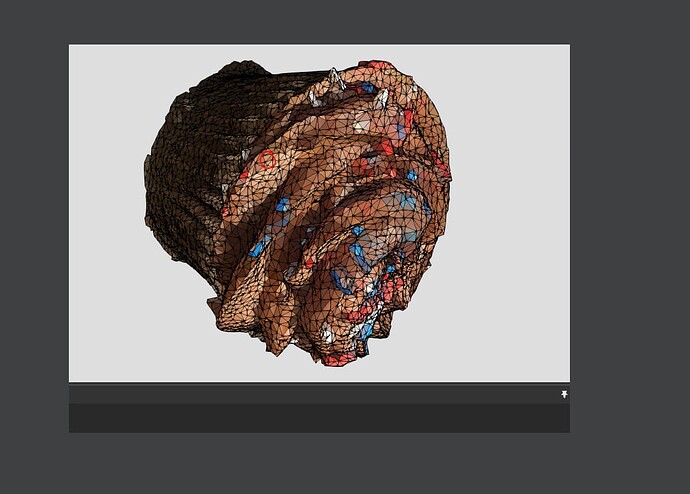

When I import the custom object we want to use it for the demo. It is displayed gridline as shown in the figure. I want to ask if is there a way to hide the grid lines.

Thanks a lot

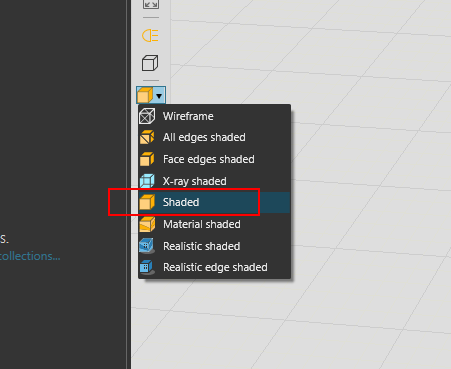

I think that happens to some CAD files like .obj and faces are created as separate geometry sets and you see the border lines on each face. I don’t remeber if there’s any easy fix for it but you could just use different shading mode like “Shaded” to not display those lines:

-k

It is work. That is great. Thanks