When at add in another operator to my process it doesn’t work correctly as the operators lift boxes and set them on the other station, is there a way to stop this from happening? (Both are connected to the same transport controller)

I still haven’t been able to solve this issue if anyone can help that would be great

Your video is not playable and the description is not detailed enough to understand what is the issue and propose solutions.

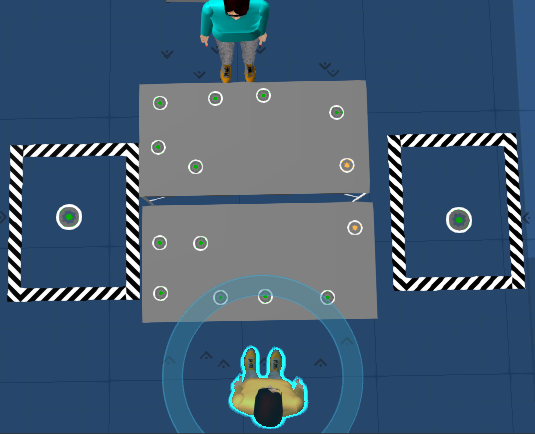

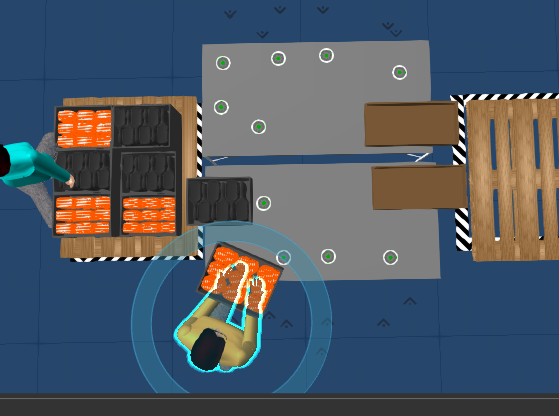

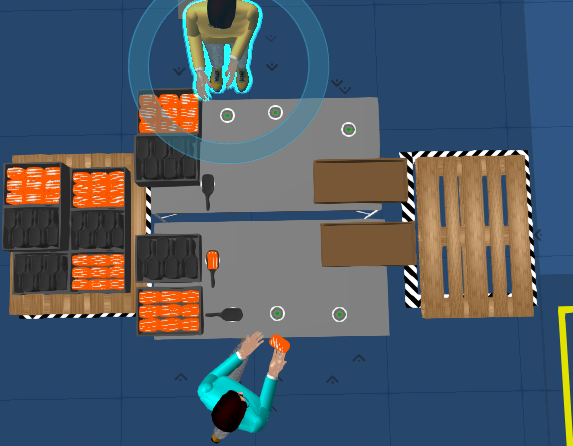

Above i posted a few snips of the issue. First issue is that i have tried to get two operators to perform the same process but at different stations, the pallet comes in and they have to lift kits to assembly both operators lift a box and goes to the same table, then goes and grabs another 2 boxes and sets the at the other table.

Second issue which i think stems from issue one this is when assembling the product, they switch tables one or twice after each product made then stay at the table til the box is empty. I guess this also is the reason why the products are not assembled right at on station as seen in on of the photos.

Ive been trying to solve this but not getting very far

I don’t fully understand the process or the issues, but I can try to give some hints:

- To keep human resource from going to do unrelated tasks, you can reserve and release it by sending certain signals from the process.

- If you need two resources to bring things to same process but not overlap physically, you can try defining two resource location frames and using those different ones in separate transport in statements.

- The transport controllers have some transport link prioritization options which might help keep the human resources working on their own side of the table together with the reservation and such.

- Modeling what happens on the table in a simpler manner with just one or two processes per workstation might make the whole thing easier to control.