Hi everyone,

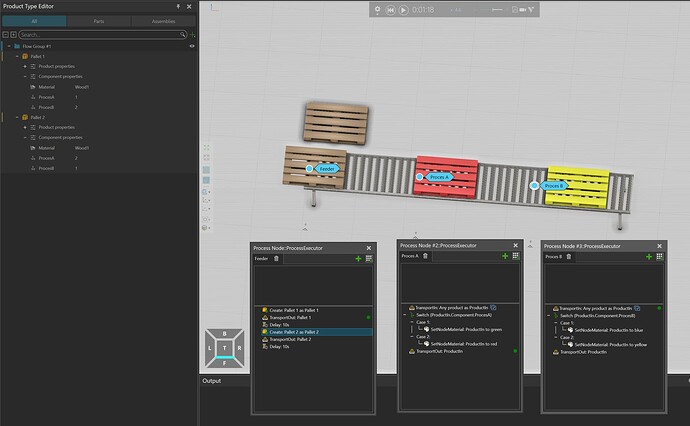

I’m currently working on a Visual Components simulation of a production line. The layout includes a conveyor system where a pallet carrying a workpiece moves through several processing cells. At each cell, the pallet stops, and a machining process is simulated.

What I would like to achieve is the following: Each pallet should carry information (for example, an array or list of numbers) that defines which operation needs to be executed at each cell. For instance, the first number in the array (e.g., “1”) would represent which specific process simulation should be triggered at the first cell, the second number for the next cell, and so on.

Based on this stored data, each cell should read the corresponding value from the pallet and then execute the matching operation simulation.

This approach reflects our real-world production system, and we would like to make our simulation as realistic as possible. Could anyone suggest how to implement this kind of logic in Visual Components? For example:

· Should this data be stored as pallet properties or as custom attributes?

· How can each process station access and interpret that data when the pallet arrives?

· Would a Python script or signal-based logic be more suitable for this?

Any tips or examples would be greatly appreciated!

Thank you in advance.