Hello all, one of my project need flip a part in one station and then robot pick the flipped part to next station. However, my program stop after one cycle without any alarm. Anybody can help solve it?

Flip process flow issue.vcmx (201.4 KB)

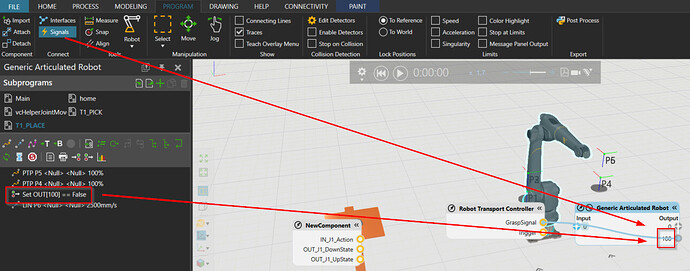

If you use the transport controller with a recorded routine like that, then you must trigger the correct signal to let the transport controller know that the transport was finished.

By default, the signal is connected to port 200, but if you change it to port 100, then it works since you use that signal in your robot program.

If you don’t really need the transport controller, you can just create a normal robot program and activate it with a signal when the part is available at a process.

Great thanks, Este! It works now after follow your recommend setting …O(∩_∩)O I’d never know the default signal 200 is connecting to the robot which use for check the transport was finished.

By the way, do you have simple way use process flow to finish this project? (Don’t use a modified recorded routine, but use the auto routine? And I also need change the Process Frame , if not the part may flip again.)

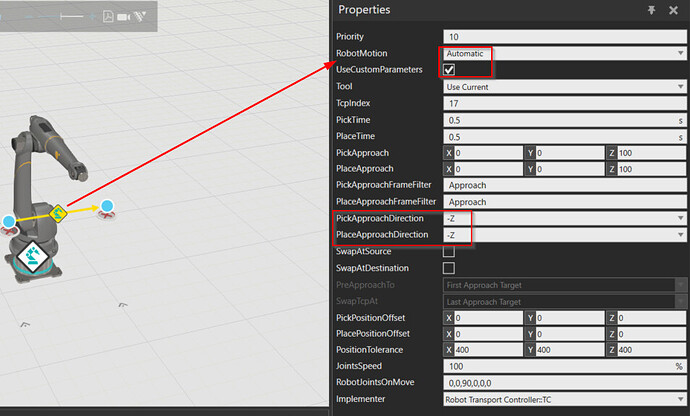

The most simple way is to use the Automatic robot motion, and set UseCustomParameters. Then, set the Pick and Place directions from +Z to -Z since the part is flipped.

![]() Thanks Este! really it works.

Thanks Este! really it works.