Hi there,

i’ve done a few layouts of production line wich all work somehow. But with every new layout if troubling around with same issues wich cost me alot oft time to trial and error. Also some issues seem to behave unlogical with makes it even hard to find the perfect solution.

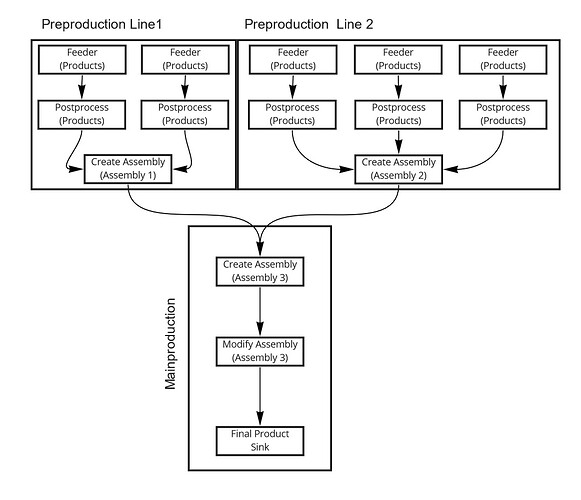

At this point I like to ask here if there is a best practice solution for this simple production setup wich can be scaled without issues. Production setup as shown:

Most Problems were i’m always unsure:

- Where to start / end a flowgroup

- Where to put the products / assemblys that it works for all flow group (mostly i put everything in one flow group to make it work, wich makes the layout messed up and unreadable)

- Best approch to send products from one flow group to another

- Make it sense to switch from assembly to a represeting product in terms of performance

Can someone give my a hint how to solve this properly or has a simple best pratice demo layout…

Thank you very much.

Best regards,

Maror