PM navigation system logic might be different from your idea, could you elaborate more or draw real example to describe your idea? Then let’s see if we can implement it.

Regarding the path requirements for AGV entry, forward, and backward directions that I mentioned, I can think of two practical examples to explain to you:

- Whether it’s a wall or other obstacle that I mentioned when I came to the door, strict requirements need to be placed on the direction of the AGV on the path in this area;

- I mentioned earlier that the Y coordinates of the TransportNode and AGV are not the same (assuming the difference in Y between these two coordinates is Ty), which requires AGV to set the resource position offset+Ty or - Ty of the shelf or other process nodes in advance when picking up and placing them on the shelf or other process nodes (the offset ± direction is determined according to the scene); In order to ensure that the “Extend” joint extends to the correct position, this scenario also requires the AGV to have a fixed direction on the resource position of the shelf or other process nodes!!! But now AGVs can only move forward by forcing+X or - X on shelves or process nodes. In some scenarios, there may be resource coordinate offsets of+Ty and - Ty for some process nodes. If AGVs can only force+X or - X to move forward, it may result in a deviation of Ty * 2 between the TransportNode and the target position when picking up or placing products at some process nodes, which can cause significant deviations in their actions!

The above two questions require the AGV to keep up with the path direction when entering, advancing, or retreating in the actual process (this type of AGV also uses adjusting the direction on each path, and even the AGV joint value requirements)

In addition, I have also discovered a serious issue. I have posted before, but it seems that I have not received a response. I feel that it is highly related to all AGVs. Problem description:

Assuming there are paths ①, ②, and ③ from A to B in a scene, AGV_1 now needs to move from A to B and has chosen path ①, During the movement of AGV1, if AGV2 suddenly occupies the ① path for a period of time, AGV1 will wait next to AGV2 or directly pass through AGV2. However, in practice, no matter what AGV, if the path to the target location is occupied for more than a certain time, the system will automatically recalculate the new path to the target based on the current position (but I am not sure if AGVs outside of China are the same, of course, this problem can be solved to some extent by using the Pathway Capacity Group component, but the workload will also increase, and it will be difficult to adjust during subsequent path version iterations). I think this problem is a core issue of AGV navigation, and I hope to receive a reply from VC official!

I really like VC software. I often use this software in my work, and the questions I raise are based on the actual project implementation process. I hope to receive attention and response from VC officials! Thank you.

Not yet.

1. Whether it’s a wall or other obstacle that I mentioned when I came to the door, strict requirements need to be placed on the direction of the AGV on the path in this area;

Could you draw a simple diagram to explain it? Current navigation system might not work that way, let’s see if we can find solution for it.

2. I mentioned earlier that the Y coordinates of the TransportNode and AGV are not the same (assuming the difference in Y between these two coordinates is Ty), which requires AGV to set the resource position offset+Ty or - Ty of the shelf or other process nodes in advance when picking up and placing them on the shelf or other process nodes (the offset ± direction is determined according to the scene); In order to ensure that the “Extend” joint extends to the correct position, this scenario also requires the AGV to have a fixed direction on the resource position of the shelf or other process nodes!!! But now AGVs can only move forward by forcing+X or - X on shelves or process nodes. In some scenarios, there may be resource coordinate offsets of+Ty and - Ty for some process nodes. If AGVs can only force+X or - X to move forward, it may result in a deviation of Ty * 2 between the TransportNode and the target position when picking up or placing products at some process nodes, which can cause significant deviations in their actions!

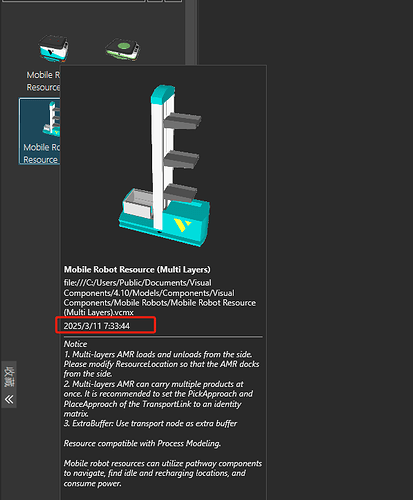

AMR will check Y axis automatically,

I’m not entirely sure about this meaning, but the current AMR will automatically adjust the extension distance of the Y-axis based on the position of the product, could you draw a simple diagram to explain it?